Dimensional Control

Capnor has a prefab dimensional control team that verifies prefabricated elements and installations, especially for facilities where extreme accuracy is required due to hazardous environment or limited time for assembly on site (e.g. offshore facilities).

Prefab dimensional control should be executed at all stages of manufacturing:

- Production

- Final acceptance

- Dispatch

The scope of our services includes (but is not limited to):

- Stake outs on site and during prefabrication

- Fitting checking and as-built measurement

- CAD-based 3D inspection

- Reverse engineering services

- Plane defining and flatness check

- Dimensional control survey services

- 3D reverse engineering services

- Reverse engineering scanning services

- Detail engineering services

Benefits:

- Limitation of on-site activities by maximizing off-site activities (reduction of construction schedule and cost)

- Elimination of re-work (maximizing work efficiency)

- Reduction of assembly time (minimizing offshore welding and fitting)

- Minimizing shutdown durations (earlier project completion)

- No surprises (risk mitigation)

Typical applications:

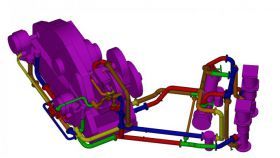

- Pipe spools

- Valves

- Fabricated assemblies

- Packaged equipment such as pump skids

- Christmas trees and associated equipment

- Tunnels, roads, bridges

- Stadiums, buildings

Production and final acceptance

Dimensional control should be performed at all production stages to identify deviations in angle or geometry of the already fabricated elements. Partial inspection mitigates the risk of costly re-work and fabrication time extension.

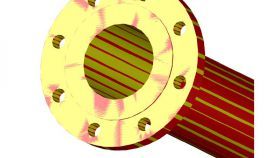

Once an item is fabricated, final quality inspection is performed. After measurements, all critical dims can be checked against the fabrication tolerances and drawings. By inspecting the finished article in 3D it is easy to measure in 3 dimensions across an object no matter where the datum is calculated from. It provides a permanent 3D record that cannot be disputed.

Maintenance

3D laser scanning along with total station measurements are used in a number of cases to identify damage or deformation across fabricated and installed elements at levels of details not possible to achieve with traditional methods. This accuracy combined with the visual 3D nature of the results makes it ideally suited for maintenance application.

Our professional control team is ready to assure our clients that there are no issues related to quality and geometry of fabricated elements. Our team immediately:

- reaches the place

- compares dimension and geometry of fabricated elements vs. detailed drawings

- solves the problem

Deliverables:

- inspection report

- CAD documentation

FAQ

1. What is dimensional control?

Dimensional control is a process of verifying the accuracy and precision of prefabricated elements and installations, ensuring they meet specified dimensional requirements. It involves measuring, inspecting, and analyzing the geometry and alignment of components to ensure they align with design specifications and tolerances.

2. What is dimensional quality control in construction?

Dimensional quality control in construction refers to the systematic process of verifying the dimensional accuracy and alignment of piping, structural, and architectural components during the construction process. It involves monitoring and inspecting dimensions to ensure compliance with design specifications, building codes, and industry standards.

3. What are the benefits of dimensional control?

The benefits of dimensional control include:

- Accuracy: Ensuring that prefabricated elements and installations meet specified dimensional requirements, reducing the risk of errors and rework.

- Efficiency: Maximizing off-site activities and minimizing on-site construction activities, leading to shorter construction schedules and reduced costs.

- Risk Mitigation: Identifying deviations early in the process, minimizing the potential for costly rework, delays, and disputes.

- Quality Assurance: Providing assurance of quality and geometry of fabricated elements through comprehensive inspection and documentation.

- Maintenance Optimization: Facilitating maintenance activities by accurately identifying damage or deformation across fabricated and installed elements, leading to efficient maintenance planning and execution.

4. What industries use dimensional control services?

Dimensional control services are utilized across various industries, including:

- Construction: For verifying the accuracy of piping spools, structural components, building systems, and architectural elements.

- Manufacturing: For ensuring the precision and alignment of machined parts, assemblies, and equipment.

- Oil and Gas: For dimensional verification of offshore platforms, pipelines, and process equipment.

- Aerospace: For inspecting aircraft components, assemblies, and tooling to meet stringent dimensional requirements.

- Automotive: For ensuring the accuracy and alignment of vehicle chassis, body panels, and assembly fixtures.

- Shipbuilding: For verifying the dimensional accuracy of ship hulls, compartments, and outfitting components.

Our services

At Capnor, we deliver engineering services that set new standards for quality and efficiency. From precise laser scanning to advanced drone photography, our innovative approach revolutionizes how you make decisions and execute projects. Trust us and focus on your goals. We will handle the rest.

Angielski

Angielski  Polski

Polski