Shaft alignment

Our company provides shaft alignment measurements and adjusting shafts between the driver and driven units with use of a laser. Capnor has Fixture Laser XA equipment for this purpose.

Precision alignment has proven to prolong the life of bearings in electric motors and the equipment they drive. Accurate alignment decreases mechanical wear on bearings and seals, and cuts down on overall vibration. It makes it possible to reduce power consumption, which in result lowers electricity costs throughout the lifecycle of the machine.

Laser shaft alignment services

Capnor excels in laser shaft alignment, employing state-of-the-art Fixture Laser XA equipment for precision measurements and adjustments. Our specialized service ensures accurate alignment between driver and driven units, enhancing the longevity and efficiency of equipment. Laser shaft alignment significantly contributes to the extended life of bearings in electric motors, reduces mechanical wear, minimizes vibrations, and ultimately lowers power consumption, resulting in substantial electricity cost savings over the equipment’s life cycle. With a commitment to high and repeatable accuracy, Capnor's laser shaft alignment services offer a superior alternative to traditional methods, ensuring optimal performance for units such as pumps, compressors, and industrial power generators.

Laser shaft alignment offered by Capnor guarantees high and repeatable accuracy, and fast execution time compared to traditional methods.

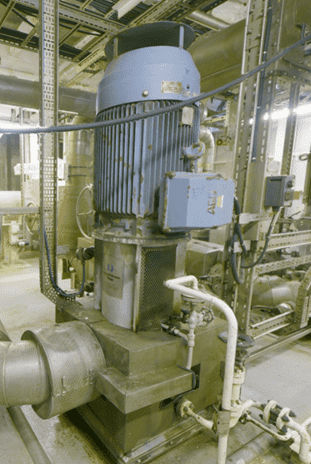

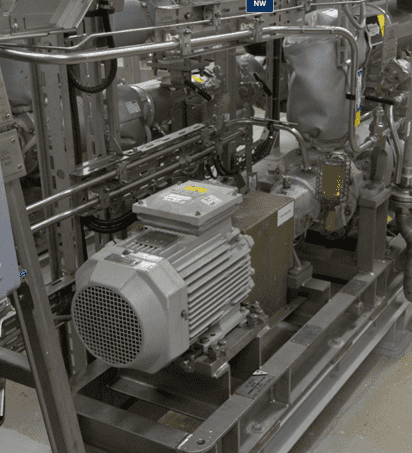

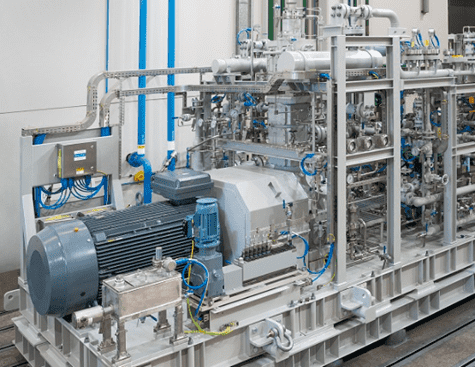

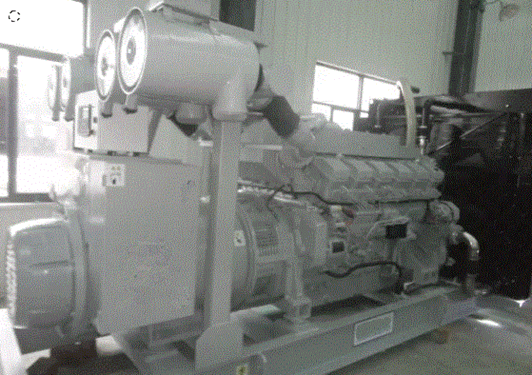

Examples of units that require shaft alignment:

Pumps

Compressors

Industrial power generators

Our services

At Capnor, we deliver engineering services that set new standards for quality and efficiency. From precise laser scanning to advanced drone photography, our innovative approach revolutionizes how you make decisions and execute projects. Trust us and focus on your goals. We will handle the rest.

Angielski

Angielski  Polski

Polski