Laser scanning

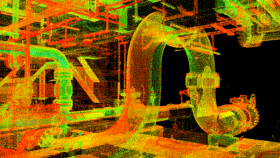

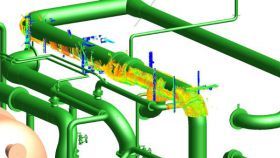

3D laser scanning is a process of digitization - capturing physical facilities’ geometry. This process provides a complete digital representation of the scanned objects to be used for feasibility study, engineering, prefabrication, and assembly processes.

The basic product of laser scanning - point cloud - can be directly used as a reference during the design process or it can serve as raw data for creation of corresponding accurate 3D CAD models, 2D drawings and other final products such as CapView images.

This helps to limit costly trips to site and reduce the risk of clashes and problems with assembly because the newly designed elements can be routed and checked within the point cloud or 3D model.

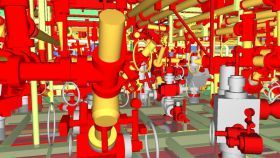

CAD models

Our CAD models can be provided in various engineering software such as PDMS / E3D, PDS / SmartPlant 3D, Inventor, AutoCAD, MicroStation, NavisWorks, SolidWorks to name but a few depending on our customer’s requirements.

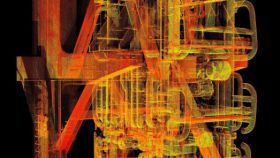

Intelligent 3D models

Laser scanning in conjunction with design or construction documentation data can be used to create fully intelligent models in PDMS. The existing model can also be adjusted to the point cloud to become an as-built model. This makes any further design in project easier and faster. The PDMS / E3D model offered by Capnor provides full spectrum of new features such as P&IDs, isometric drawings, reports, stress analyzes and MTOs. All the above mentioned documentation (but not only) can be produced directly from the PDMS / E3D model, ensuring accuracy and consistency of data.

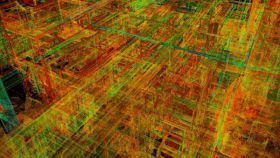

Laser Scanning for Buildings & Constructions

Capnor's 3D laser scanning services revolutionize the sector of buildings and constructions by leveraging advanced 3D technology to digitize structures for feasibility studies, design engineering, prefabrication, and assembly. The resulting point cloud serves as a reliable reference, reducing on-site visits and minimizing clashes during design. Our CAD models, compatible with various software, offer intelligent solutions with features like P&IDs and isometric drawings. The Ayelix portal enhances project management by providing online access to comprehensive information and facilitating real-time clash verifications. Our Virtual/Augmented Reality solutions offer immersive experiences, while portable arm laser scanners ensure precise quality control and efficient data collection for various applications in the building and construction sector.

Ayelix portal

Ayelix, our in-house developed tool is a state-of-art solution for every project owners and participants:

- online access to all required information (3D scans combined with HD pictures)

- easy navigation in High Resolution panorama

- see and identify objects from up to 4 different positions

- check the coordinates and measure missing elements

- retrieve full HD colored point clouds directly from the portal

- upload design 3D model and check its integration to existing objects

- perform clash verification on real time

- order additional scanning of missing elements using interactive maps

Virtual / Augmented Reality

Imagine you can be anywhere, imagine you can visit a facility without leaving your office. Imagine your device can recognize and connect real objects with your design, e.g. isometric drawings.

Thanks to our application you can move within a 3D environment either in a traditional way or with use of 3D goggles.

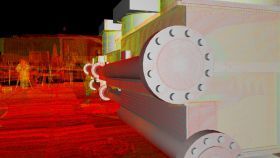

Portable arm laser scanning

Capnor uses measuring arm laser scanners primarily for the quality control of geometries and surface, but also for reverse engineering, fit and finish, and assembly applications.

- High-quality scan data collected at full speed, whatever the part.

- Scan 99 percent of surface types with default exposure settings thanks to SHINE technology.

- Extra-wide scan line for faster part coverage.

- High-quantity data collection without sacrificing data quality.

- Horizontally oriented scan line for more comfortable measurement.

- Projected laser range finder makes correct scanner positioning simple.

- Full System Scanning Certification defined according to ISO 10360-8 Annex D.

FAQ

1. What is the scanning method of laser?

Laser scanning, also known as 3D laser scanning, utilizes a laser beam emitted from a scanner to measure the distance to an object's surface. The scanner records millions of points on the object's surface, creating a point cloud that represents its geometry in three dimensions. This method allows for highly accurate and detailed digitization of physical structures and environments.

2. What is laser scanning used for?

Laser scanning is used for various purposes, including:

- Feasibility Studies: Assessing the viability of projects by capturing accurate measurements and data of existing structures or environments.

- Engineering: Providing precise measurements and point clouds for design, analysis, and simulation purposes.

- Prefabrication: Generating detailed models to aid in the prefabrication of components for construction projects.

- Assembly Processes: Assisting in the planning and execution of assembly processes by ensuring accurate alignment and fit of components.

- Quality Control: Conducting thorough inspections of manufactured parts or structures to ensure compliance with specifications and standards.

3. What is the principle of laser scanning?

The principle of laser scanning involves emitting laser beams toward an object and measuring the time it takes for the beams to return to the scanner after reflecting off the object's surface. By calculating the distance based on the time of flight or phase shift of the laser pulses, the scanner generates a point cloud representing the object's geometry. This point cloud can then be processed to create detailed 3D models or for various analytical purposes.

4. Is LiDAR the same as laser scanning?

LiDAR (Light Detection and Ranging) is a specific type of laser scanning technology that uses laser pulses to measure distances to objects. While laser scanning generally refers to the broader concept of using lasers for 3D digitization, LiDAR specifically refers to the use of laser pulses in remote sensing applications, such as topographic mapping, forestry, and atmospheric research. However, in some contexts, the terms "laser scanning" and "LiDAR" are used interchangeably.

5. What industries use laser scanning?

Laser scanning is utilized across a wide range of industries, including:

- Construction: For building and infrastructure projects, including surveying, design, and quality control.

- Engineering: In mechanical, civil, and aerospace engineering for design, analysis, and reverse engineering.

- Architecture: For building documentation, preservation, and restoration projects.

- Manufacturing: In automotive, aerospace, and manufacturing industries for quality control and process optimization.

- Forensics: In crime scene investigation and accident reconstruction.

- Oil and Gas: For pipeline and facility inspections, as well as asset management.

6. How much do laser scanning services cost?

The cost of laser scanning services can vary depending on factors such as the size and complexity of the facility, the level of detail required, the equipment used, and the provider's rates. Typically, laser scanning services are priced based on factors such as scanning time, time and software used for scan data processing and conversion, and any additional services required (e.g., CAD modeling, analysis). It's advisable to consult with a provider to obtain a customized quote based on the specific requirements of your project.

- reduction of measurement time

- high accuracy of 3D digital data

- no rework and clashes

- reduced design and assembly hours

- efficient decision making

- increased safety on site

- convenient data visual presentation

- shortened schedules and deadlines

- limited costs in all project phases

Our services

At Capnor, we deliver engineering services that set new standards for quality and efficiency. From precise laser scanning to advanced drone photography, our innovative approach revolutionizes how you make decisions and execute projects. Trust us and focus on your goals. We will handle the rest.

Angielski

Angielski  Polski

Polski