3D Engineering

3D engineering is our own term for the comprehensive engineering behind additive manufacturing (3D printing), 3D scanning and reverse engineering. Our aim is to be a one stop company for our clients to be able rely on an honest approach to quality, sourcing and engineering for their projects.

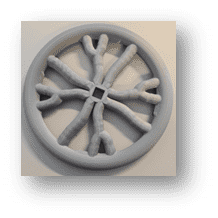

3D Printing Services

We have a quality FDM printer in-house but one of our advantages is that we are not dependent on using any special printer. We will use the best and most cost-efficient vendor available for the specific project, either new parts or repairs. We will make sure the vendor prints quality parts according to standards such as DNVGL-ST-B203 or equivalent.

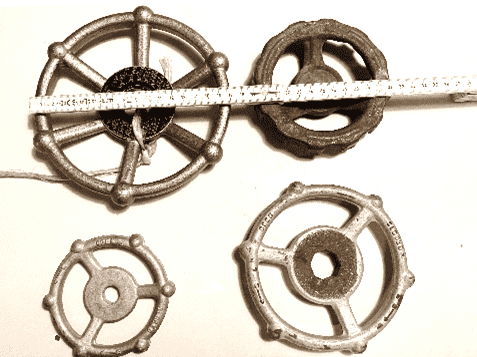

Digitization Services

Capnor provides digitization services, employing 3D scanners to capture detailed digital renditions of physical components. This service is particularly beneficial for obsolete parts without proper documentation. Our expertise in reverse engineering allows us to transform scanned data into accurate CAD files, optimizing them for efficient production and ensuring functionality. Whether you need ad hoc digitization or a strategic approach to reduce physical inventory, Capnor has you covered.

We have 3d scanners able to scan parts. Such types of scans will digitize parts -especially useful for obsolete parts with missing documentation. We are able to reverse engineer the part to a proper CAD file and optimize it for production and function as well. One may want to digitize parts ad hoc or with a strategy to reduce physical inventory or to have an insurance of old parts.

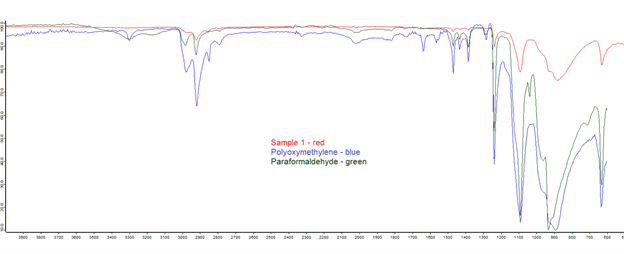

Material Testing Services

We have a cooperation with the University of Stavanger on material testing. This ensures that we have the best possible personnel and equipment available. Our own experience after years of material testing ensures that we are able to perform testing both within and outside the scope of normal standards. Some projects require thinking outside the box and to have a pragmatic approach to deliver the results the client needs.

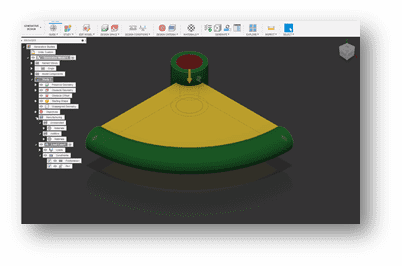

Optimization Services

Very often, parts which have been made by traditional methods such as milling, lathing, extrusion, casting and so on are made with the respective production method during design. We will make sure the parts are optimized both for function and for production. Very often generative design will be the most cost efficient method.

3D Scanning Services

Capnor offers cutting-edge 3D scanning services, utilizing advanced technology to capture precise digital representations of physical parts. Our 3D scanning expertise is particularly valuable for digitizing components, especially in cases of obsolete parts lacking documentation. Whether digitizing parts on an ad hoc basis or implementing a strategic approach to reduce physical inventory, we excel in reverse engineering, transforming scans into accurate CAD files optimized for production and functionality.

3D Modeling Services

As part of our comprehensive 3D engineering services, Capnor specializes in 3D modeling to ensure optimal design and functionality. We go beyond traditional production methods, such as milling and casting, by leveraging generative design to optimize parts for both function and production. Our commitment is to deliver cost-efficient solutions that meet the highest standards of quality and performance.

Angielski

Angielski  Polski

Polski