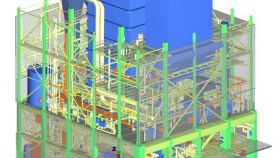

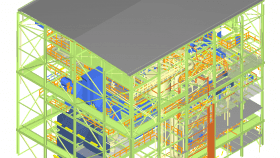

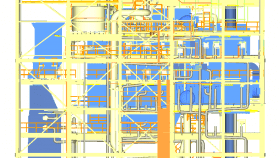

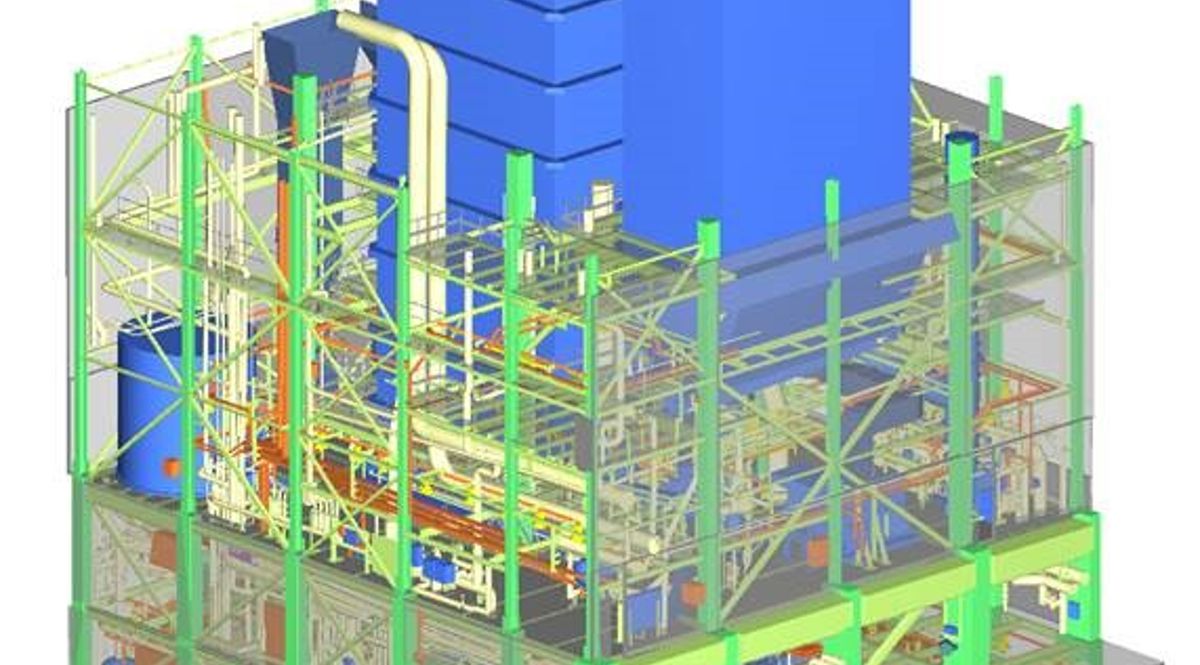

BFB boiler

Location

Świecie, Poland

Scope of Work

- 3D laser scanning and TPS measurements

- scan data processing to achieve a point cloud

- 3D modeling (DGN, STP and MAC formats)

Due to lack of updated as-built documentation, laser scanning technology was required in order to quickly receive the geometric information of the BFB boiler building. The reason for this was to make engineering works more efficient and avoid clashes. First, the boiler building structures including equipment between ground level (+0.0) and +20.600 were covered with scans and modeled. Then, the remaining levels (up to +50400) were ordered (the second part of the project is being executed). The model converted to PDMS included the following disciplines: structural, piping, equipment, and electrical.

Our services

At Capnor, we deliver engineering services that set new standards for quality and efficiency. From precise laser scanning to advanced drone photography, our innovative approach revolutionizes how you make decisions and execute projects. Trust us and focus on your goals. We will handle the rest.

Angielski

Angielski  Polski

Polski